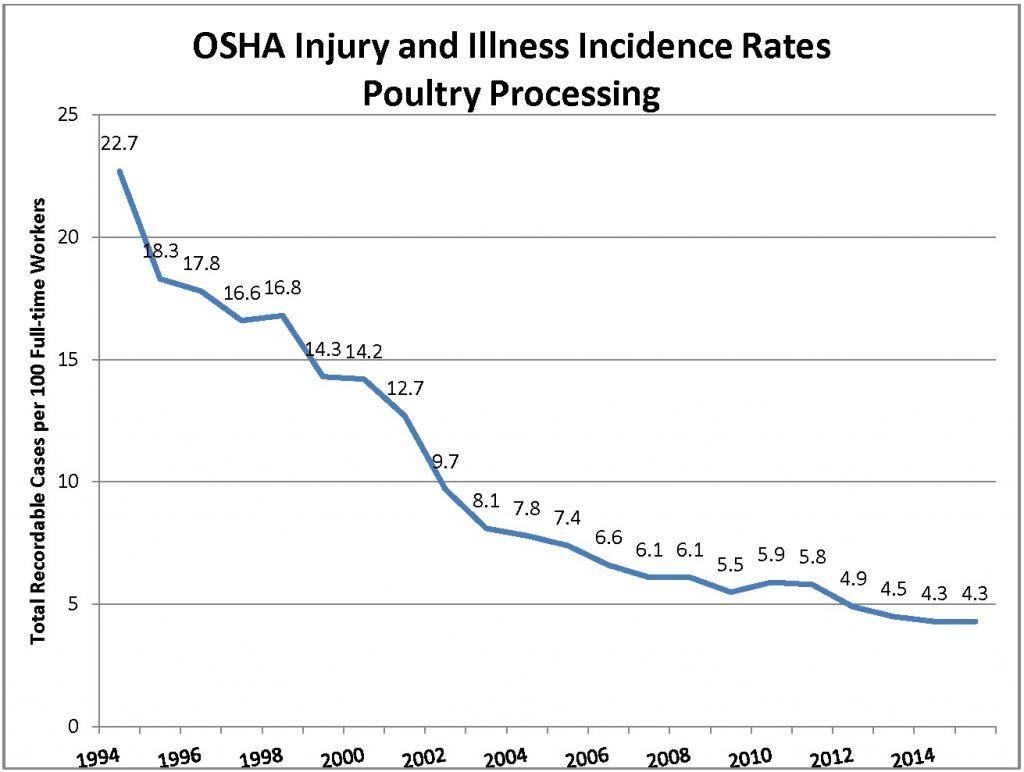

The poultry industry is proud of the advancements in worker safety that have been made over the last 30+ years and the ongoing efforts for continued improvement. The incidence of occupational injuries and illnesses within the poultry sector’s slaughter and processing workforce has fallen by 81 percent in the last 20 years and continues to decline according to the 2014 Injury and Illness Report released by the Department of Labor’s Bureau of Labor Statistics (BLS).

Perhaps more than any other industry, the poultry industry over the last several decades has focused its energies on the prevention of workplace injuries and illnesses, especially musculoskeletal disorders like carpal tunnel syndrome, by recognizing the value of implementing ergonomics principles. Companies also adhere to Occupational Safety and Health Administration’s (OSHA) recommended guidelines that further help protect poultry workers.

Continued Improvement

While the past 25 years has seen a dramatic decrease in the numbers and rates injury and illnesses occurring in the industry, the poultry industry will continue to seek new and innovative ways to protect our workforce. Ongoing efforts to improve the poultry industry’s record in worker safety include:

- Sharing non-competitive practices, culminating with the release of a whitepaper, Ergonomics in the Poultry Industry – A Review of 25 Years of Industry Efforts, which documents many of the industry’s efforts to improve worker safety;

- Partnering with the Georgia Tech Research Institute to develop an instrument to assess musculoskeletal disorder (MSD) risks in poultry tasks. The tool will measure upper extremity stresses associated with poultry deboning and cutting tasks, and provide quantitative data to help in workstation and tool redesign and process workflow improvements to reduce the stresses and strains associated with repetitive work;

- Continuing to work with equipment manufacturers and suppliers to improve machine guarding on new equipment and the provision of adequate disconnects to assist and facilitate proper lock out/tag out (LOTO) procedures;

- Collaborating with personal protective equipment suppliers. This has led to improvements in cut resistance of protective handwear, reduced fogging issues with safety eyewear, and improved slip resistance in safety footwear to address lacerations, foreign objects/splashes and slip, trips and falls;

- Conducting monthly meetings of the Poultry Industry Safety & Health Committee to share best practices in hazard identification and risk control; and

- Holding an annual safety conference for the past 31 years – the National Safety Conference for the Poultry Industry. The June 2012 conference highlighted such things as “recognizing combustible dust hazards,” “hot topics in industrial hygiene” and roundtable discussions covering many topics including machine guarding, fall protection and catastrophic event planning and response.

How does the poultry processing’s rating stack up against the injury and illness rating of other industries?

To find out more about modern poultry inspection, go to chickeninspectionfacts.com.